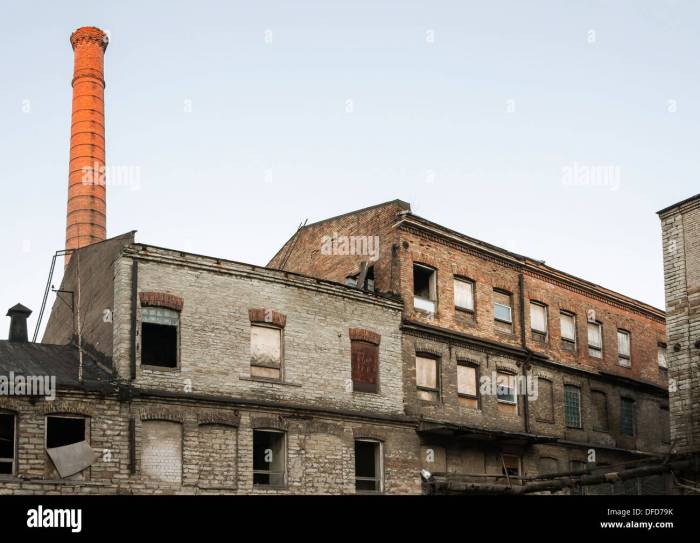

Transforming a derelict industrial building into a vibrant, modern space presents a unique set of challenges and rewards. These structures, often steeped in history, possess a raw, undeniable character, but their age often brings structural instability, hazardous materials like asbestos and lead paint, and complex regulatory hurdles. This journey into the world of industrial building renovation explores the multifaceted process, from navigating the initial assessment and demolition strategies to the careful integration of modern technology and sustainable practices, all while respecting the building’s unique heritage.

The process demands a meticulous approach, balancing preservation with modernization. We will delve into the intricacies of structural repairs, the environmental considerations involved in handling hazardous materials, and the crucial legal and permitting processes. Furthermore, we’ll explore design choices that blend industrial aesthetics with contemporary functionality, emphasizing sustainable practices to minimize environmental impact and maximize energy efficiency. Ultimately, this guide aims to provide a comprehensive understanding of the complexities and possibilities inherent in breathing new life into these architectural giants.

Challenges of Renovating Old Industrial Buildings

Renovating old industrial buildings presents a unique set of challenges that go beyond the typical residential or commercial renovation. These structures, often built with materials and techniques reflecting their era, require specialized knowledge and careful planning to ensure both structural integrity and worker safety. The inherent complexities, combined with potential environmental hazards, significantly impact the project’s timeline and budget.

Common Structural Issues in Aging Industrial Buildings

Aging industrial buildings frequently exhibit structural weaknesses stemming from decades of wear and tear, often exacerbated by initial construction methods. Common issues include compromised load-bearing walls weakened by corrosion, settling foundations resulting in uneven floors and cracks, and deteriorated timber framing susceptible to rot and insect infestation. The use of older materials, like unreinforced masonry, presents particular challenges, requiring extensive assessment and potentially significant reinforcement or replacement.

For instance, a building constructed in the early 20th century might have load-bearing walls made of brick laid without modern mortar techniques, leading to instability over time. Furthermore, the absence of modern seismic design in older structures necessitates careful analysis and reinforcement to meet current building codes, especially in seismically active regions.

Environmental Concerns During Renovation

Renovation of old industrial buildings often unearths significant environmental concerns. Asbestos, a known carcinogen, was widely used in insulation and fireproofing materials until its ban in the late 1970s. Lead-based paint, another hazardous material, was common in older structures and poses a risk during demolition and renovation if disturbed. The presence of these materials mandates specialized abatement procedures, adding substantial cost and time to the project.

For example, a pre-demolition asbestos survey might reveal extensive asbestos-containing insulation in pipework, necessitating a complete abatement before any structural work can begin. Similarly, lead paint found on window frames would require careful scraping and disposal according to EPA guidelines. Ignoring these hazards can result in significant health risks and hefty legal penalties.

Hypothetical Renovation Project Cost Breakdown

Let’s consider a hypothetical 10,000 square foot industrial building renovation. A realistic cost breakdown might look like this:

| Cost Item | Estimated Cost | Percentage of Total |

|---|---|---|

| Pre-demolition surveys (asbestos, lead) | $10,000 | 2% |

| Abatement (asbestos, lead) | $50,000 | 10% |

| Structural repairs and reinforcement | $200,000 | 40% |

| MEP (Mechanical, Electrical, Plumbing) upgrades | $150,000 | 30% |

| Interior finishes | $50,000 | 10% |

| Contingency (unexpected expenses) | $40,000 | 8% |

| Total Estimated Cost | $500,000 | 100% |

The contingency budget accounts for unforeseen issues, such as discovering hidden structural damage or encountering unexpected environmental hazards. In reality, unexpected expenses frequently exceed initial estimates, emphasizing the need for a robust contingency plan. For example, discovering extensive water damage behind a wall during demolition could easily add tens of thousands of dollars to the project cost.

Comparison of Demolition Techniques

Several demolition techniques are applicable to old industrial buildings, each with its advantages and disadvantages. Selective demolition involves carefully removing portions of the structure, preserving valuable elements while removing hazardous or damaged sections. This method is slower and more expensive but minimizes waste and environmental impact. Full demolition, on the other hand, involves complete razing of the structure, often employing heavy machinery like excavators and wrecking balls.

This is quicker and generally cheaper but generates significant waste and may disrupt surrounding areas. Implosion is a specialized technique used for large structures, involving controlled collapse to minimize debris scatter. The choice of technique depends on factors like the building’s size, condition, location, and environmental regulations. A large, structurally unsound building in a densely populated area might necessitate implosion to ensure safety and minimize disruption.

Building Materials Suitability for Renovation

Choosing appropriate materials is crucial for successful renovation. The following table Artikels the suitability of various materials:

| Material | Structural Suitability | Environmental Impact | Cost | Durability |

|---|---|---|---|---|

| Steel | High | Moderate | High | High |

| Reinforced Concrete | High | Moderate | Moderate | High |

| Recycled Timber | Moderate | Low | Moderate | Moderate |

| Engineered Wood | High | Moderate | Moderate | High |

Preservation and Modernization Techniques

Renovating old industrial buildings presents a unique opportunity to blend historical preservation with modern functionality. The challenge lies in carefully balancing the desire to retain the building’s character with the need to incorporate contemporary technologies and design elements for optimal energy efficiency and modern living or working spaces. This requires a multi-faceted approach encompassing material selection, structural reinforcement, and the integration of smart systems.Successful renovations hinge on a deep understanding of the building’s original construction and its inherent strengths and weaknesses.

This knowledge, combined with innovative preservation techniques and the strategic implementation of modern technologies, ensures a sustainable and aesthetically pleasing outcome.

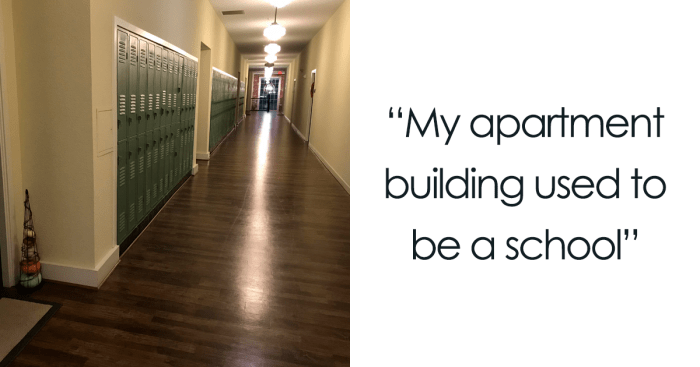

Examples of Successful Industrial Building Renovations

The adaptive reuse of industrial buildings has yielded numerous successful projects worldwide. For example, the conversion of former textile mills in Lowell, Massachusetts, into residential lofts showcases the successful preservation of exposed brick walls, high ceilings, and large factory windows, which are now defining features of the modern apartments. Similarly, the transformation of old warehouses in New York City’s SoHo district into upscale boutiques and art galleries demonstrates the potential to integrate original structural elements with modern commercial spaces.

These renovations often involve retaining original timber beams, cast-iron columns, and even original machinery as striking architectural elements, demonstrating the value of integrating history into contemporary design. The key is to carefully assess the structural integrity of these elements and implement appropriate preservation methods, such as chemical treatments for wood preservation or specialized coatings to protect metalwork.

Integration of Modern Technology

Modern technology plays a crucial role in enhancing the functionality and energy efficiency of renovated industrial buildings. Smart home systems, for instance, allow for centralized control of lighting, heating, ventilation, and security, significantly reducing energy consumption and improving occupant comfort. These systems can be seamlessly integrated into the existing infrastructure, often utilizing wireless technology to minimize disruption to the building’s original aesthetic.

Furthermore, the use of smart sensors can monitor energy usage in real-time, providing valuable data for optimizing energy performance and identifying areas for improvement. For example, a system could automatically adjust lighting based on occupancy and natural light levels, or optimize heating and cooling based on real-time temperature data and occupancy patterns.

Improving Insulation and Energy Efficiency

Improving insulation is paramount in achieving energy efficiency in a renovated industrial building. Old industrial buildings often lack adequate insulation, resulting in significant heat loss during winter and heat gain during summer. Retrofitting with modern insulation materials, such as spray foam insulation, cellulose insulation, or mineral wool, can significantly improve the building’s thermal performance. These materials can be strategically applied to walls, ceilings, and floors, minimizing thermal bridging and maximizing insulation effectiveness.

Furthermore, high-performance windows and doors can dramatically reduce heat transfer through the building envelope. Triple-glazed windows, for instance, offer superior insulation compared to traditional single- or double-glazed windows. Finally, air sealing is critical to prevent air leakage, which is a major contributor to energy loss. This can be achieved by sealing cracks and gaps in walls, floors, and ceilings using caulk, weatherstripping, and other appropriate sealing materials.

Step-by-Step Process for Adapting Industrial Space

The adaptation of an industrial space for residential or commercial use follows a structured process:

- Assessment and Planning: A thorough assessment of the building’s structural integrity, existing utilities, and environmental conditions is crucial. This phase includes identifying potential challenges and developing a detailed renovation plan, incorporating preservation goals and modern requirements.

- Structural Reinforcement: Addressing any structural deficiencies is vital before proceeding with renovations. This may involve reinforcing existing load-bearing elements, repairing damaged components, or adding new structural supports.

- MEP Systems Upgrade: Modernizing mechanical, electrical, and plumbing (MEP) systems is essential for functionality and safety. This often involves replacing outdated wiring, plumbing, and HVAC systems with energy-efficient alternatives.

- Insulation and Energy Efficiency Measures: Implementing the insulation and energy-efficiency improvements detailed above is crucial for long-term sustainability and cost savings.

- Interior Design and Construction: This phase involves the actual construction and interior design, incorporating both preserved historical elements and modern amenities.

- Finishing Touches: Final touches, such as lighting fixtures, flooring, and interior decoration, are incorporated to create a functional and aesthetically pleasing space.

Sample Floor Plan for a Renovated Industrial Building

Imagine a former warehouse, approximately 10,000 square feet. The original brick walls and high ceilings (16 feet) are retained. The floor plan could incorporate an open-plan living area with exposed brick, a modern kitchen with stainless steel appliances integrated seamlessly into the industrial aesthetic, and two bedrooms with ensuite bathrooms. A mezzanine level, supported by original steel columns, could create additional living space, perhaps a home office or library, maintaining the building’s open feel while adding functional space.

The original loading dock could be converted into a private garden or outdoor terrace, bringing natural light and green space into the living area. This design demonstrates the successful integration of original industrial elements with modern living spaces.

Legal and Regulatory Aspects

Renovating an old industrial building presents a complex legal landscape, demanding meticulous navigation to ensure compliance and avoid costly delays or legal repercussions. Understanding the relevant regulations and obtaining necessary permits are crucial for a successful project. Failure to do so can result in stop-work orders, fines, and even legal action. This section details the key legal and regulatory considerations involved.

Required Permits and Approvals

Securing the necessary permits and approvals is the cornerstone of any legal renovation project. The specific permits required vary significantly depending on the location, the extent of the renovations, and the nature of the building itself. Generally, permits are needed for demolition, structural alterations, electrical work, plumbing, HVAC systems, and fire safety upgrades. These are typically obtained from local building departments or similar regulatory bodies.

For example, a project involving significant structural changes might require architectural plans reviewed and stamped by a licensed professional, accompanied by a detailed application demonstrating compliance with building codes. A simple interior renovation might require fewer permits, but obtaining even minor permits is still essential for legal compliance. It is imperative to thoroughly research and understand the specific requirements of the relevant jurisdiction before commencing any work.

Zoning Regulations and Their Impact

Zoning regulations dictate the permissible uses of land and buildings within a specific area. These regulations can significantly influence renovation plans, potentially restricting the type of use, building height, density, and parking requirements. For instance, an old industrial building located in a zone designated for residential use might face restrictions on converting it into commercial space. Before initiating renovations, a thorough review of the zoning ordinances is critical.

This review should identify any potential conflicts between the planned renovations and existing zoning regulations. In some cases, variance applications might be necessary to obtain approval for renovations that deviate from the existing zoning rules. This process often involves public hearings and demonstrating that the proposed changes serve the public interest and do not negatively impact the surrounding area.

Obtaining Historical Preservation Permits

If the building is listed on a local, state, or national register of historic places, obtaining historical preservation permits becomes mandatory. These permits ensure that renovations are carried out in a manner that preserves the building’s historical integrity. The process usually involves submitting detailed renovation plans to the relevant historical preservation agency for review and approval. This review scrutinizes the proposed changes to ensure they are compatible with the building’s historical significance and architectural features.

Agencies often have specific guidelines and requirements regarding materials, techniques, and even the color palette used in the renovations. The goal is to balance the need for modernization with the preservation of the building’s historical character. Failure to comply with these requirements can lead to penalties and project delays.

Liability Issues Related to Hazardous Materials

Old industrial buildings often contain hazardous materials such as asbestos, lead paint, and PCBs. The presence of these materials poses significant liability risks. Before starting any renovation work, it is crucial to conduct a thorough environmental assessment to identify the presence and extent of any hazardous materials. This assessment should be performed by qualified professionals who are experienced in identifying and mitigating the risks associated with these materials.

Failure to properly address the presence of hazardous materials can lead to significant health problems, environmental damage, and substantial legal liabilities. The legal responsibility for the safe removal and disposal of hazardous materials rests with the property owner. Appropriate remediation plans, adhering to all relevant environmental regulations, must be developed and implemented. This might involve specialized contractors certified to handle hazardous materials.

Detailed documentation of the remediation process is essential for legal protection.

Legal Requirements Checklist for a Hypothetical Renovation Project

This checklist Artikels essential legal steps for a hypothetical renovation project of an old industrial building. This is not exhaustive and specific requirements vary widely based on location and project scope. Always consult with legal and environmental professionals for guidance.

- Conduct a thorough title search to ensure clear ownership and identify any encumbrances.

- Review zoning regulations and obtain necessary zoning approvals.

- Perform an environmental assessment for hazardous materials (asbestos, lead, PCBs).

- Develop and implement a remediation plan for hazardous materials if necessary.

- Submit complete building plans to the local building department for review and approval.

- Obtain all necessary building permits (demolition, structural, electrical, plumbing, HVAC).

- Secure permits related to historical preservation, if applicable.

- Comply with all relevant safety regulations throughout the renovation process.

- Maintain detailed records of all permits, approvals, inspections, and remediation activities.

- Obtain necessary insurance coverage for the project, including liability insurance.

Design Considerations and Aesthetics

Transforming a derelict industrial building into a vibrant, functional space requires a delicate balance between preserving its historical character and integrating modern design elements. The aesthetic choices made significantly impact the building’s final character, influencing its usability and market value. Successful renovations seamlessly blend the raw, industrial past with contemporary needs, creating spaces that are both stylish and practical.

Architectural Styles Suitable for Industrial Building Renovations

Several architectural styles lend themselves well to the renovation of industrial buildings. The raw, exposed elements inherent in many industrial structures often provide a strong foundation for styles that celebrate industrial history, such as adaptive reuse of existing structural components. For example, a former warehouse might be renovated in a style echoing its original purpose, emphasizing exposed brick and steel beams.

Alternatively, a more contemporary aesthetic could be adopted, such as minimalist designs that contrast sleek lines and modern materials against the building’s rough texture. A loft-style conversion, often characterized by high ceilings, open floor plans, and large windows, is another popular choice, capitalizing on the inherent spaciousness of many industrial buildings. Finally, industrial chic, which blends raw industrial elements with luxurious finishes, is a growing trend.

The Use of Exposed Brick, Metal, and Other Industrial-Style Elements

Exposed brick, metal, and other industrial elements are key components of a successful industrial renovation. The texture and color variations in exposed brick walls add character and warmth, providing a visually rich backdrop for modern furnishings. Steel beams, often left visible, become architectural features, highlighting the building’s history. Other industrial elements, such as ductwork, piping, and concrete flooring, can be strategically incorporated to enhance the aesthetic.

However, careful consideration must be given to the structural integrity and potential hazards associated with these elements. For instance, exposed piping might require insulation or protective coatings for safety and energy efficiency. The integration of these elements must be balanced with the incorporation of contemporary materials and finishes to avoid a stark, cold, or unfinished look.

Balancing Historical Preservation with Modern Design Aesthetics

The challenge in renovating an industrial building lies in harmoniously blending historical preservation with modern design aesthetics. This involves identifying and preserving significant architectural features, such as original brickwork, structural elements, and window designs. Simultaneously, modern amenities and technologies need seamless integration. For example, new HVAC systems might be cleverly concealed within existing structural elements, preserving the visual integrity of the space.

Modern lighting fixtures can be chosen to complement the industrial aesthetic, while high-performance glazing in new windows can enhance energy efficiency without compromising the building’s character. The use of reclaimed materials, such as recycled wood or metal, can further enhance the sustainable and historically sensitive nature of the project. This approach avoids creating a jarring juxtaposition between old and new, resulting in a cohesive and aesthetically pleasing space.

Lighting Plan for a Renovated Industrial Space

A well-designed lighting plan is crucial in creating the desired ambiance and functionality in a renovated industrial space. The high ceilings characteristic of many industrial buildings offer opportunities for dramatic lighting effects. A combination of ambient, task, and accent lighting can be employed to achieve both functionality and atmosphere. Ambient lighting, such as recessed lighting or pendant fixtures, provides overall illumination.

Task lighting, using desk lamps or track lighting, focuses light on specific work areas. Accent lighting, strategically placed spotlights, highlights architectural features such as exposed brick or steel beams. The use of warm-toned LED lighting can create a welcoming atmosphere, while cooler tones can be employed in work areas to enhance focus. Dimmers and smart lighting controls can provide flexibility in adjusting the lighting levels to suit different moods and activities.

Consider incorporating natural light through large windows, maximizing daylight penetration and minimizing the need for artificial lighting during the day.

Mood Board: Renovated Industrial Building Aesthetic

Imagine a space where the rich texture of exposed brick walls in a deep, earthy red-brown hue provides a dramatic backdrop. The brick is punctuated by the cool, metallic sheen of reclaimed steel beams, painted a matte charcoal grey. The flooring is polished concrete, a light grey with subtle veining, reflecting light and creating a sense of spaciousness.

Furnishings are a mix of vintage industrial pieces, such as repurposed metal chairs and wooden workbenches, juxtaposed with sleek, modern sofas and armchairs upholstered in rich, textured fabrics like dark grey wool or brown leather. Lighting is a combination of industrial-style pendant lamps with exposed Edison bulbs, providing warm, ambient light, and strategically placed spotlights highlighting the architectural features.

The overall color palette is a sophisticated blend of warm greys, deep browns, and accents of metallic charcoal, creating a space that is both industrial and refined, a testament to the building’s past while embracing a modern, comfortable aesthetic. The textures are a key component, combining the rough texture of the brick and steel with the smooth surfaces of the concrete and polished metal, adding depth and visual interest.

Sustainable Renovation Practices

Renovating an old industrial building presents a unique opportunity to champion sustainable practices, minimizing environmental impact while enhancing the building’s lifespan and value. By thoughtfully incorporating eco-conscious materials and technologies, we can transform these structures into models of responsible development, demonstrating that historical preservation and environmental stewardship can coexist harmoniously. This section details key strategies for achieving sustainable renovation in such projects.

The core principle of sustainable renovation lies in reducing the building’s environmental footprint throughout its lifecycle. This encompasses material selection, construction methods, energy efficiency, and water conservation. The benefits extend beyond environmental responsibility, including cost savings through reduced energy consumption and improved building performance, enhanced occupant health and well-being, and increased property value due to its eco-friendly features.

Recycled and Sustainable Material Selection

The use of recycled and sustainable materials significantly reduces the demand for newly extracted resources, thereby lowering carbon emissions associated with manufacturing and transportation. Reclaimed wood, for example, offers a unique aesthetic appeal while reducing deforestation. Recycled steel, often sourced from demolition projects, possesses comparable strength to new steel, minimizing embodied carbon. Similarly, incorporating rapidly renewable materials like bamboo or sustainably harvested timber reduces the environmental burden compared to traditional options.

The selection of materials with high recycled content and low embodied carbon should be prioritized throughout the renovation process. For instance, using recycled concrete aggregates in new concrete mixes can reduce the overall carbon footprint significantly. A case study of the adaptive reuse of a former textile mill in Massachusetts demonstrated a 30% reduction in embodied carbon by prioritizing recycled materials.

Waste Minimization Strategies

Minimizing waste during renovation is crucial for environmental responsibility and cost efficiency. Careful planning and precise material ordering are paramount. Detailed waste audits prior to commencement, allowing for accurate waste projections, help optimize disposal and recycling strategies. On-site sorting and separation of materials (wood, metal, concrete, etc.) facilitate efficient recycling and reduce landfill waste. The implementation of lean construction principles, emphasizing waste reduction and efficiency, is also highly beneficial.

For example, prefabrication of components off-site can reduce on-site waste and improve construction speed. A project renovating a former factory in London achieved a 95% waste diversion rate through meticulous planning and on-site recycling programs.

Green Building Technologies

Integrating green building technologies enhances energy efficiency and reduces operational costs. High-performance insulation, such as spray foam insulation or dense-packed cellulose, minimizes energy loss through the building envelope. The installation of energy-efficient windows and doors further reduces heat transfer. Employing solar panels for renewable energy generation can significantly decrease reliance on the grid. Geothermal heating and cooling systems offer a sustainable and efficient alternative to conventional HVAC systems.

These technologies, when integrated effectively, contribute to a substantial reduction in a building’s carbon footprint. A study conducted by the Lawrence Berkeley National Laboratory demonstrated that green building technologies can reduce energy consumption by 20-30%.

Water Efficiency Improvements

Implementing water-saving technologies is essential for sustainable renovation. Low-flow plumbing fixtures (toilets, showerheads, faucets) reduce water consumption significantly. Water-efficient landscaping, utilizing drought-tolerant plants and rainwater harvesting systems, minimizes reliance on municipal water supplies. Greywater recycling systems, which reuse wastewater from showers and sinks for irrigation, can further conserve water resources. The integration of smart water meters allows for precise monitoring of water usage, facilitating proactive adjustments and identifying potential leaks.

The implementation of these measures can lead to substantial water savings, reducing both environmental impact and operational costs. For example, a renovated warehouse in California achieved a 40% reduction in water usage through the implementation of these water-saving technologies.

Natural Light and Ventilation Strategies

Maximizing natural light and ventilation reduces reliance on artificial lighting and mechanical ventilation systems. Strategic placement of windows and skylights allows for ample daylight penetration, minimizing the need for electric lighting during daytime hours. The incorporation of operable windows and strategically placed vents facilitates natural ventilation, reducing the need for air conditioning, especially during milder weather. The design should consider prevailing wind patterns and solar orientation to optimize natural ventilation and daylighting.

Studies have shown that buildings with abundant natural light and ventilation can reduce energy consumption by 15-25%. A renovated office building in Seattle successfully incorporated these principles, achieving a significant reduction in energy costs.

Wrap-Up

Renovating an old industrial building is a complex undertaking, a delicate dance between preserving history and embracing modernity. From grappling with structural integrity and environmental hazards to navigating legal complexities and designing sustainable spaces, the journey demands meticulous planning and expert execution. However, the rewards are substantial: the creation of unique, character-filled environments that seamlessly blend historical charm with contemporary functionality.

By carefully considering each stage, from initial assessment to final design, and by prioritizing sustainable practices, we can ensure that these industrial relics are not only restored but also contribute to a more environmentally responsible future.

Common Queries

What are the typical insurance considerations for renovating an old industrial building?

Insurance costs are significantly higher for industrial building renovations due to the inherent risks involved, including structural instability, hazardous materials, and potential worker injuries. Comprehensive liability insurance, workers’ compensation, and specific coverage for asbestos abatement are crucial.

How long does the entire renovation process typically take?

The timeline varies dramatically depending on the building’s size, condition, scope of renovations, and permitting processes. Smaller projects might take several months, while larger, more complex ones can extend to several years.

What are some common financing options for industrial building renovations?

Financing options include traditional bank loans, commercial mortgages, historical preservation grants (if applicable), and private investors. Securing funding often requires a detailed business plan and a thorough assessment of the project’s feasibility.

How can I find qualified contractors experienced in industrial building renovations?

Seek referrals from architects, engineers, and other professionals familiar with this type of work. Thoroughly vet potential contractors, checking references, licenses, and insurance coverage. Review past projects and ensure they possess the necessary expertise and experience.

What are the potential resale value implications of renovating an old industrial building?

The resale value depends heavily on location, the quality of the renovation, market demand, and the building’s unique features. Well-executed renovations that incorporate modern amenities and sustainable practices often command a premium.

Leave a Reply